In the worker's perspective, it's crucial to understand that there's no specific workplace exposure standard or limit for heat stress, and heat stress indices should be viewed only as guides, not definitive safe/unsafe limits.

Determining a safe/unsafe limit solely based on ambient air temperature is inadequate, considering the various factors (task, environment, and individual) influencing the onset of heat strain.

Recognizing and managing heat stress goes beyond simply considering air temperature. Accurate identification and assessment involve evaluating:

- Workplace conditions

- Job requirements

- Individual worker attributes.

To effectively address heat-related illness risks, a thorough workplace survey is essential. Engage with workers to gather insights into their experiences with heat stress. Explore the workplace's history of heat-related issues, noting the specific circumstances and times they occurred.

Key questions to include in a heat investigation:

- What are the potential sources of heat in the workplace?

- Have there been previous instances of heat stress problems, and if so, when and under what conditions?

- How do workers minimize their exposure to thermal energy?

- Is there an existing thermal stress management program in place?

- Does the program include training and information on heat stress awareness?

- What remedial actions have been taken to reduce thermal loading on workers?

- Are there any comments or concerns raised by workers regarding heat stress?

Addressing these questions comprehensively ensures a more nuanced understanding of heat stress factors, enabling WorCover Queensland to implement effective measures to safeguard workers in varying conditions.

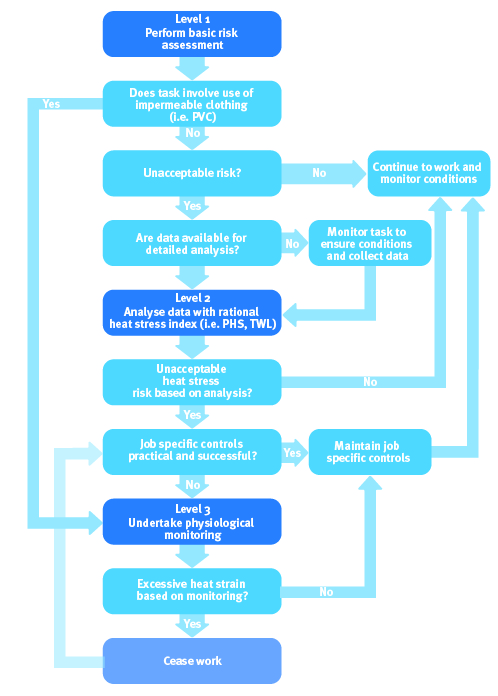

Use the following three level approach to identify heat stress factors in your workplace (Di Corleto et al 2013, refer figure 1).

Level 1 (Non-technical): is a basic risk assessment, which can use a simple index such as the Heat stress (basic) calculator.

Heat stress (basic) calculator is a simple online tool designed for use by anyone with basic knowledge of the work area and process. There is no direct measurement of environmental conditions required to use the calculator.

The online calculator uses a number of factors to make a basic assessment of heat stress including:

- the state of acclimatisation

- work demands, location

- clothing

- sun exposure

- hot surfaces

- task complexity

- air movement, and other factors

- apparent temperature (this is calculated using ambient temperature and relative humidity).

The online calculator is an initial qualitative review of potential heat stress situations and is not a definitive assessment tool.

A level 2 (technical) assessment will be needed when:

- the online calculator identifies an unacceptable level of heat stress risk

- impermeable clothing is worn.

Level 2 (Technical): needs additional data collected and the use of a second level index such as ISO 7933: Predicted Heat Strain (PHS) or Thermal Work Limit (TWL). A range of measuring equipment and expertise is required for this type of assessment.

Additional data needed for this type of assessment will include:

- dry bulb temperature

- globe temperature

- air velocity

- humidity

- metabolic load

- clothing type

- posture.

This type of assessment and gathering of required data should only be undertaken by a competent person such as an occupational hygienist or occupational physician.

The University of Queensland (UQ) has developed a smart phone app based on ISO 7933, called PHS, visit The Thermal Environment for more information.

A level 3 (expert) assessment will be needed when either:

- data cannot be collected

- where impermeable clothing is used.

Level 3 (Expertise): Physiological monitoring

Physiological monitoring is used in cases of high heat stress risk such as:

- work involving the use of encapsulating suites (e.g. hazmat suits) or high levels of external PPE

- environments where the level 2 assessment indicates allowable exposure times of less than 30 minutes

- where a work environment cannot be accurately assessed.

The risk and severity of heat related illness will vary widely among workers, even under identical heat stress conditions. Individual monitoring measures a worker's physiological responses (such as elevated body temperature and/or heart rate) to assess the effectiveness of implemented controls.

To manage the risks associated with heat, workers need to adopt two main strategies: adjusting the environment to match the work requirements and modifying the work to suit the prevailing conditions. It's crucial to carefully consider suitable control measures, as certain measures are more practical in specific situations. In many cases, a combination of controls is necessary.

Adapting the Environment for Work:

- Manage heat sources by reducing their temperature before commencing work.

- Insulate hot surfaces to safeguard against contact burns.

- Employ radiant heat shields or barriers with good insulation properties and low emissivity/high reflectivity.

- Utilize shade barriers, such as temporary gazebos, to shield the work area from the sun.

- Implement ventilation, air conditioning, and air movement to replace hot/humid air with cooler/drier air. This can be achieved through mechanical or natural means, such as fans or exhaust systems.

Adapting the Work to the Environment:

- Modify work processes by using mechanical aids like cranes and conducting tasks at ground level or in shaded areas.

- Provide rest areas or refuges for workers to escape the heat, ideally located near the work area.

- Implement administrative controls, such as worker selection and scheduling work during cooler times.

- Encourage work-rest intervals in cool places with ample cool water for fluid replacement.

Personal Protective Equipment (PPE):

- Choose appropriate PPE to minimize adverse effects on the body's heat balance.

- Examples include wearing hats for sun protection, vented safety eyewear, and light-colored, reflective clothing.

- Use specialized cooled or conditioned PPE, such as air circulating systems or liquid cooling suits.

Training:

- Train workers on mechanisms of heat exposure, potential exposure situations, recognizing predisposing factors, the importance of fluid intake, acclimatization, effects of alcohol and drugs, early symptoms of heat illness, prevention, and first aid treatment.

- Encourage self-assessment and explain the benefits of medical surveillance programs.

Maintenance and Review of Controls:

- Regularly assess the effectiveness of controls.

- Confirm that available controls are used by workers when needed.

- Evaluate if there are better controls that could be implemented for improved risk management.

Using the Heat stress (basic) calculator during training helps workers input various control combinations to enhance the risk score. Regular reviews ensure that controls are not only in place but also functioning effectively.