As a worker, it's essential to be aware of the various ways our skin can come into contact with substances at work, potentially causing harm and diseases. Certain chemicals, when in contact with the skin, can be absorbed and lead to diseases in other parts of the body.

Understanding how to stay safe is crucial. Skin exposure may happen through contact with cleaning products, oils, paints, adhesives, and even foodstuffs. Additionally, work activities that generate contaminants, like welding fumes, wet cement, and wood dust, can pose risks.

Industries with a higher likelihood of skin exposure include food services, construction, cleaning and maintenance, hairdressing and beauty therapy, health and community care, metalworking, motor vehicle repair, and printing.

It's important to note that wet work, defined as work involving more than 20 hand washes per shift or having wet hands for more than two hours per shift, can damage the skin.

Seeking medical advice for skin conditions resulting from occupational exposure is crucial, especially for severe allergic reactions that may require immediate attention.

The skin, acting as a two-way barrier, plays a vital role in protecting our bodies. However, it's important to recognize that some contaminants can easily pass through intact skin, posing risks. Broken skin, such as rashes, cuts, and scratches, as well as very dry or frequently wet and dried skin, is at an increased risk of absorbing contaminants.

Frequent wetting and drying, or the use of alcohol-based hand sanitizers, can strip the skin of fats, making it dry and more susceptible to potential harm. Taking proactive measures to protect our skin is essential in maintaining overall health and well-being.

There are four main types of contaminants that can harm the skin:

| Contaminant type | Potential harm |

|---|---|

| Corrosives | Burns |

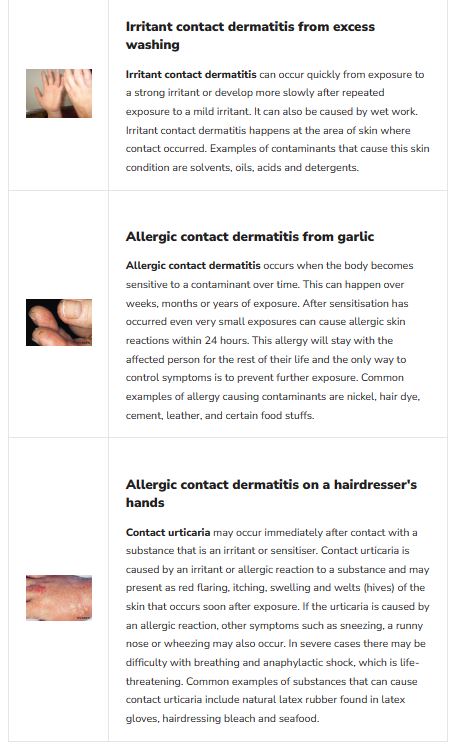

| Irritants | Irritant contact dermatitis |

| Sensitisers | Allergic contact dermatitis |

| Those that cause other diseases | Skin infections |

Skin absorption

Some contaminates can be readily absorbed through the skin and cause health effects in other areas of the body. Examples include:

| Contaminant | Area affected |

|---|---|

| Aromatic amines | Bladder (cancer) |

| Mineral oils | Scrotum (cancer) |

| Benzene | Blood (leukemia) |

| Organophosphates | Nervous system (muscle weakness) |

A safety data sheet will provide information on whether a chemical is harmful via skin absorption.

Managing exposure

Identification

Identify processes that may involve skin exposures. Safety data sheets, technical data sheets and labels on products are a good source of information.

View some examples of irritants and sensitisers that workers can be exposed to:

Occupation | Irritants that can cause irritant contact dermatitis | Sensitisers that can cause allergic contact dermatitis |

Abattoir workers | Acids, alkalis, detergents, waste products, wet-work | Animal proteins, formaldehyde, latex gloves, nickel |

Cleaners | Detergents, other cleaning products, solvents, wet-work | Formaldehyde, germicidal agents |

Construction workers | Cement, dusts, solvents, sand, wet-work | Cement, chromium, cobalt, epoxy resins, nickel, resins, wood dust, isocyanate based products |

Cooks and caterers | Acids, alkalis, bleaching agents, detergents, vegetable juices, wet-work | Some flavours, formaldehyde, garlic, sodium metabisulphite, spices |

Hairdressers | Bleaching agents, dyes, perming solutions, shampoos, wet-work | Dyes, nickel, persulphates, perfumes, latex gloves, amine based chemicals |

Health care workers | Disinfectants, detergents, wet-work | Latex gloves, local anaesthetics, antibiotics, antiseptics, formaldehyde, glutaraldehyde |

Metal workers | Cutting fluids, solvents, metal shavings/dust, wet-work | Additives/preservatives in cutting fluids, chromium, nickel |

Motor vehicle repairers | Aggressive hand cleaners, fuels, oils, paints, solvents | Chromium, cobalt, epoxy resins, nickel |

Printers | Solvents | Colophony, formaldehyde, metals in inks & resins, hardeners, turpentine |

Fishing, trawling or seafood handling | Fish products, wet-work | Seafood |

Control the risks

Stop or reduce the exposures:

Where possible, stop using products or doing work activities that can harm the skin or cause disease

- Use encapsulated machines or automated equipment such as dishwashers or parts washers.

Use a less harmful material or substance

- A less concentrated substance

- A water-based product instead of solvent based product.

Use products in a form that is less likely to be absorbed into the skin

- Instead of liquids or powders use pellets or granules

- Follow the manufacturers or suppliers suggested dilution rates for chemicals.

Cover cuts as these may provide a route of entry for substances.

Control the exposures:

Separate workers from the hazard.

Enclose the process, handling system or contaminant

- Use a glove box

Create a safe working distance between the skin and contaminants

- Use tools and equipment such as tongs, hooks and scoops.

Prevent incidental contact with contaminants- Use good housekeeping practices to ensure surfaces are kept clean.

Protect the skin:

Good skin care including, proper hand washing, hand drying and using a skin lotion to moisturise the skin and prevent drying will help to maintain the skin's integrity and reduce the risk of irritant and allergic contact dermatitis developing.

Barrier creams do not protect against absorption of substances.

Personal protective equipment (PPE)

PPE may be needed if it is not possible to avoid skin contact using other control measures. Several PPE items may be needed to protect the worker. How much depends on the level of potential contamination and can include a combination of overalls, goggles, face shield, respirator, gloves and/or boot covers.

The personal protective equipment film shows how to correctly and safely put on, wear and remove PPE. It also shows how to dispose of it.

Gloves

No one type of glove will suit every work task, every contaminant and every worker.

When choosing the right glove, consider:

- the work activity

- if dexterity is required for the task

- the type of glove for the process (short cuff or arm length)

- the length of time it takes to conduct the task

- whether the task involves chemical splashes or immersion

- whether cotton glove liners are required to reduce sweating in hot conditions

- the worker

- provide a range of different sizes to fit individual workers

- minimise the risk of latex allergies by choosing powder free non-latex gloves

- the contaminant

- the breakthrough time of the specific chemical

- the potential lifespan of the gloves

- a glove selection guide.

Glove manufacturers often produce selection guides that can be used to choose the most suitable glove. The Ansell 8th Edition Chemical Resistance Guide and the Prochoice Hand Protection Guide are two examples of manufacturer's glove selection guides.

Before gloves are worn, ensure they are inspected for integrity, remove and replace gloves if they appear damaged or break-through occurs.

Once gloves are removed it is important to wash hands in case of accidental contamination.

Skin hazard:

- Chemical splashes causing burns to skin.

How to prevent exposure:

- use racks to hold metal parts

- have lifting equipment to dip and remove product from acid baths

- use a rinse bath after dipping to prevent handling items coated in chemicals.

Personal protective equipment required:

- Chemical resistant face shield, apron and boots.

Glove Selection:

Salon hair washing/hair dying

Skin hazard:

- hair dyes (p-phenylenediamine)

- wet work.

How to prevent exposure:

- task rotation

- following manufacturer's instructions on correct use of chemicals

- don't reuse disposable gloves.

Glove selection:

Training: Implementing a worker training initiative can enhance awareness of specific skin exposure risks in the workplace and underscore the importance of safeguarding the skin. Key topics to address include:

- Identifying specific skin hazards in the workplace

- Understanding the health effects of exposure to contaminants

- Exploring controls used to minimize skin exposure

- Recognizing early warning signs of skin disease

- Familiarizing with first aid procedures for chemical contact or splashes

- Learning effective handwashing techniques and principles of personal hygiene

- Understanding the correct procedures for putting on and taking off single-use and reusable gloves.

Maintenance and Review of Controls: Even if you have the appropriate controls in place to protect workers' skin, it's crucial to assess their effectiveness.

Consider the following questions:

- When were the controls last inspected or evaluated?

- Are workers using controls when necessary?

- Is there a more effective control that could be implemented?

Health Monitoring: Certain chemicals that require health monitoring can be readily absorbed through the skin. It is imperative to ensure that health monitoring is provided to workers engaged in ongoing activities involving the use, handling, generation, or storage of specific substances (such as chromium, creosote, and poly-aromatic hydrocarbons). This is especially crucial when there is a significant risk to the worker's health due to exposure. Additional guidance on determining significant risk can be found in Safe Work Australia's "Health monitoring for exposure to hazardous chemicals - Guide for persons conducting a business or undertaking."