For other sectors such as manufacturing, service, office, amusement, and rural industries, the pertinent information is outlined in the Electrical Safety Regulation 2013. Additionally, AS/NZS 3760, which delves into the in-service safety inspection and testing of electrical equipment, offers further insights into this process.

Who can test electrical equipment?

Only a person appointed as competent by their employer can test and tag electrical equipment.

Competence is based on knowledge and skills gained from training, experience, qualifications or a combination of these. It is an offence under the Electrical Safety Act 2002 to repair electrical equipment unless you have the appropriate electrical work licence.

Tagging electrical equipment

A durable tag must be attached after inspecting and testing to clearly show the test date and the next scheduled test and inspection date.

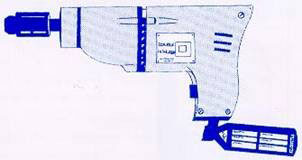

A tool showing the inspection and testing tag (blue impact drill with tag off handle).

Intervals for testing specified electrical equipment

The type of work being performed determines how often specified electrical equipment is tested. Specified electrical equipment is defined by section 97 of the Electrical Safety Regulation 2013 as electrical equipment with a current rating of not more than 20 amps*. Specified electrical equipment also includes cord extension sets and electrical portable outlet devices (EPODs). *For service or office work, specified equipment is limited to equipment that is moved during its normal use for the purpose of its use.

The table below outlines the maximum interval between tests.

Note: there are specific requirements on a hire company for inspecting, tagging and testing hire equipment.

| Type of work and/or equipment | Test and tag interval (maximum) |

|---|---|

| Amusement devices and rides (not specified) (A device or ride supplied by a plug with a current rating of not more than 20 amps must also be connected to a type 1 safety switch or type 2 safety switch) | After each onsite assembly, and every 6 months |

| Amusement work - double insulated specified equipment | 12 months |

| Amusement work – specified equipment not double insulated | 6 months |

| Construction work – transportable structures, fixed and transportable equipment and construction wiring | 6 months |

| Construction work – other equipment | 3 months |

| Manufacturing work – double insulated equipment | 12 months |

| Manufacturing work – equipment not double insulated | 6 months |

| Office work (If no safety switch) | 5 years |

| Rural work – equipment used under stated risk factors* and no safety switch | 12 months |

| Service work (If no safety switch) | 12 months |

*See section 120 of the Electrical Safety Regulation 2013 for stated electrical risk factors

Intervals for testing Type 1 and Type 2 safety switches

For all other work, refer to the Electrical Safety Regulation 2013.

The type of work being performed determines how often safety switches are tested. The table below outlines the maximum interval between tests.

For construction work, refer to AS/NZS 3012 Electrical installations – Construction and demolition sites.

For all other work, refer to the Electrical Safety Regulation 2013 and, where applicable, AS/NZS 3760 In-service safety inspection and testing of electrical equipment.

If the equipment is safe you must attach a durable tag which shows when the next test is due.

| Type of work | Fixed safety switch | Portable safety switch | ||

|---|---|---|---|---|

| | Push-button user Test | Operating time / current test | Push-button user Test | Operating time / current test |

| Construction work | 1 month | 12 months | Daily, or before each use, whichever is the longer | 3 months |

| Manufacturing work | 6 months* | 12 months* | Daily, or before each use, whichever is the longer*# | 12 months*# |

| Office work | 6 months* | 2 years* | 3 months* | 2 years* |

| Amusement work | 6 months* | 12 months* | 3 months* | 12 months* |

| Service work - commercial cleaning equipment | N/A | N/A | Daily, or before each use, whichever is the longer* | 6 months* |

| Service work - other | 6 months* | 2 years* | 6 months* | 2 years* |

*Longer test intervals may apply. Consult AS/NZS 3760 In-service safety inspection and testing of electrical equipment.

# From 1 March 2008 portable safety switches were prohibited from use in manufacturing work

Equipment that fails testing should be immediately ;taken out of use and a durable tag must be attached warning people not to use the equipment. If the equipment is safe you must attach a durable tag which shows when the next test is due.